#Petrochemical Additives ·2024-09-10

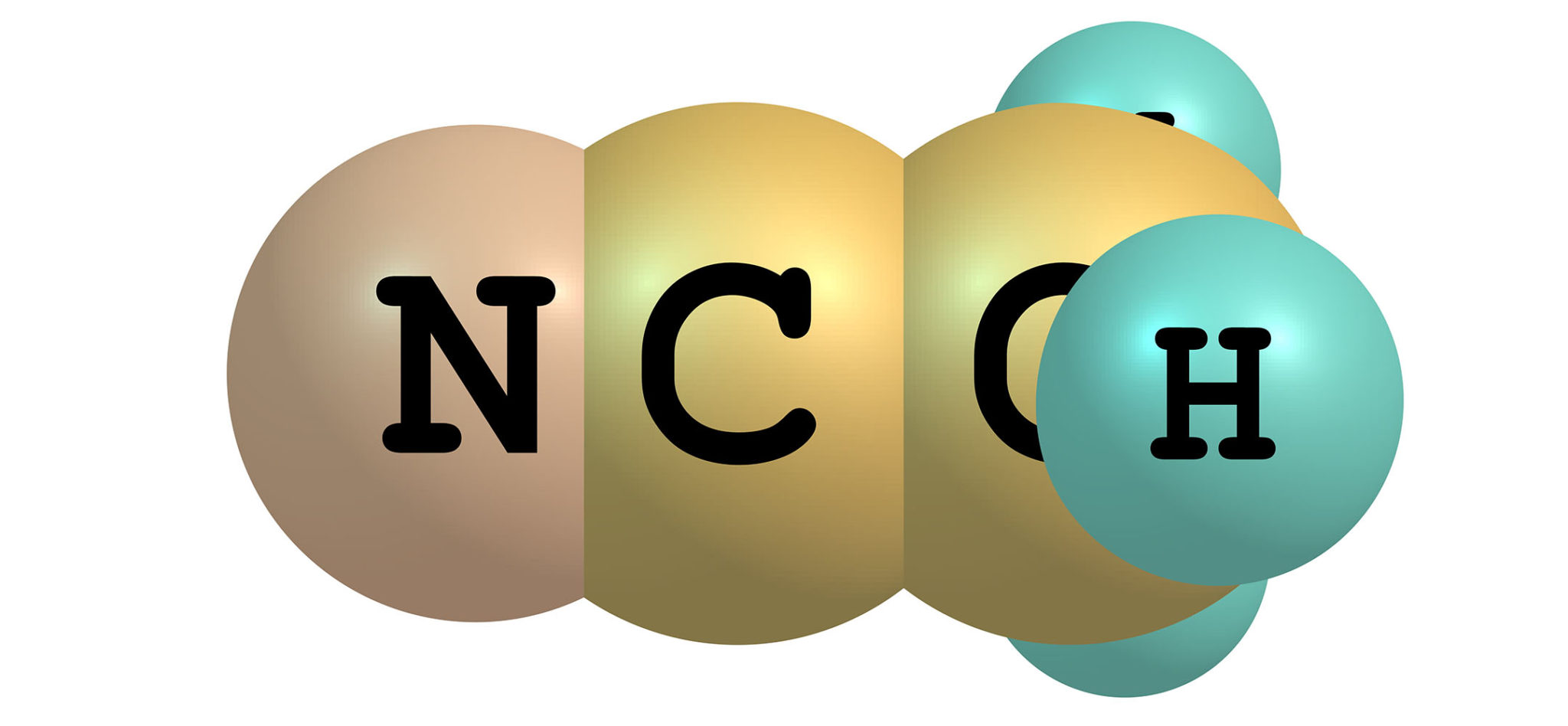

At Cestoil, we are dedicated to providing innovative and high-performance chemical solutions for the petrochemical industry. Our acrylonitrile plant antifoulants are specifically designed to tackle the challenges faced during the synthesis, distillation, storage, and transportation of active monomers like acrylonitrile, acrylic acid, esters, and styrene, which can easily polymerize when heated. By utilizing Cestoil’s effective antifoulants, you can significantly improve the efficiency of your operations and minimize downtime in your acrylonitrile production processes.

Active monomers like acrylonitrile are prone to polymerization when exposed to heat during synthesis, distillation, storage, and transportation. This process can lead to the formation of viscous, gel-like substances or powdery solids that adhere to equipment surfaces or accumulate on tower trays. Such buildups can hinder normal production processes and, in severe cases, lead to explosive polymerization, making the cleaning of reactors and distillation equipment extremely challenging. Frequent shutdowns due to these issues can result in reduced production and waste of valuable raw materials.

Cestoil’s high-performance acrylonitrile plant antifoulants offer a multitude of benefits that help optimize your production processes:

Cestoil is committed to delivering innovative and efficient solutions for the petrochemical industry. Our acrylonitrile plant antifoulants are specifically engineered to address the challenges of polymerization, ensuring smoother operations and reduced downtime. By choosing Cestoil’s antifoulants, you can enhance your plant’s efficiency, extend the lifespan of your equipment, and maintain the quality of your end products—all while contributing to a sustainable and environmentally friendly production process.

To learn more about our acrylonitrile plant antifoulants or to discuss your specific needs, please contact our team of experts today. We look forward to partnering with you to optimize your operations and enhance the overall efficiency of your acrylonitrile production facility.

You can send us a general question inquiry here